Vibration analysis

Short descriptiVibration analysis is one of the most important services of Chaco Commercial Engineering Company, which will be performed by our team with the most advanced industrial equipment and devices. If you want to receive various status monitoring services, contact Chacko’s professional engineers.on of the service

- Click to get information

Vibration analysis services

Managers of various industries to reduce the cost of maintenance activities and repairs (net) of industrial equipment from various techniques such as; Corrective maintenance, preventive maintenance, emergency maintenance, comprehensive productive net, etc. are used. In these techniques, it is necessary to identify defects and breakdowns of the equipment in different ways and perform maintenance and repairs in order to fix them. Vibration analysis services, along with methods such as oil analysis, ultrasonic analysis, thermography, etc., are among the most common methods of detecting mechanical defects in equipment, which are performed by the Chaco website and using the best technicians.

How are vibrations created in equipment?

All industrial equipment and devices vibrate during their operation, and this issue is their inseparable feature and is forced in power transmission mechanisms, the amount of vibration is different in different devices. A new and healthy device always has a minimum vibration range, which amount will not cause damage to the device, but gradually with the operation and depreciation of the device, over time, its components will be gradually eroded and its looseness will increase, and finally, the vibrations Undesirable, which cause excessive load on various components of the device and the cause of energy loss, and cause the deterioration of the device and accelerate its failure.

What is the analysis of the primary frequency of vibrations?

Every vibration movement of industrial equipment and machinery, with three features; Amplitude, frequency and phase are identified, which are actually the three characteristics of vibration measurement criteria. The amplitude will express the magnitude of the vibration signal and show the mechanical defects of the equipment and the severity of their defects; So that the bigger the range of vibrations, the more the vibrations of the device will be, and as a result, the mechanical fault will be more acute.

What does the amplitude of vibration depend on?

In vibration testing, the vibration range in the industry depends on the type of device, so that this characteristic is measured with the vibration range of a similar new and healthy device. In the vibration test, the permissible limits of vibration for devices and different operating conditions are also determined in the standards by the manufacturers. In the technique of the condition monitoring system, the vibration level of the device is measured with the help of special sensors of the analysis device, for this purpose, the displacement, speed or acceleration parameters of the vibrations will be measured. In the vibration testing technique, the decision regarding the selection of the measurement parameter should be made carefully and according to the working conditions of the devices and the measurement objectives.

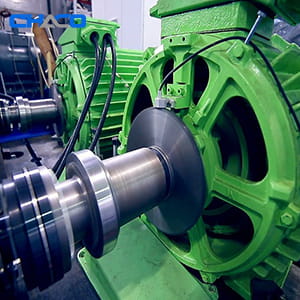

Service images

What forms can be determined by measuring vibration?

In the technique of vibration analysis, the value of the vibration amplitude of the device is a suitable measure of its health status because the vibration has high stability and little influence of environmental factors, hence this technique along with other techniques for monitoring the status of rotating equipment such as; Oil analysis, flow analysis, etc., will be a suitable parameter to use as a condition monitoring technique. This technique is used for troubleshooting in various equipment, so that many defects and mechanical failures of rotating equipment appear in the form of vibration symptoms or changes in the vibration characteristics of the system.Since every failure or mechanical problem has its own vibration symptoms, therefore, the cause of vibration can be identified in this way. Major mechanical failures that cause vibration symptoms in the equipment include; Unbalance, misalignment, bending of shafts, creating looseness, wear and erosion of the rotor, cracking and failure of all kinds of bearings, failure of gears, coupling and belt defects, etc.

Pump vibration analysis

Pump vibration analysis is another method of monitoring the condition of industrial machines, which can reduce the costs of a manufacturing company by using it in the industry. We at Chacko guarantee you to transform your business by using the best vibration analysis devices. Pumps, including key equipment and its vibration analysis, are among the most important programs of condition monitoring methods, through which one can be informed of failures in time and prevent further losses by performing preventive repairs, as well as in the use of industrial parts and also It saved the time of manpower in maintenance and repair of machines and finally led an organization to gain more. If you are looking for pump vibration analysis services, stay with chaco in this section.

Analysis of fan vibrations

Fan vibration analysis is one of the most important services provided by Chacko Commercial Engineering Company. Fan vibration analysis is one of the standard methods for diagnosing problems and failures of various types of defects in rotating equipment such as bearings and fan belts, which is used to monitor the condition of rotating equipment. The technique of vibration analysis is one of the standard methods for diagnosing problems and failures of various types of defects in rotating equipment such as bearings and belts of fans, which is used to monitor the condition of rotating equipment. With the help of this method, it is easy to detect and repair defects and failures in time before the problems and failures of bearings or belts or other parts increase and prevent further financial losses. If you are looking for fan vibration analysis services, stay with Chacko in this section to get more complete information about this.

How is the vibration analysis service performed?

The use of vibration analysis technique for the purpose of vibration measurement of industrial equipment will lead to the detection of unauthorized vibration and mechanical defects of the equipment, which can reduce the vibration in the devices by performing maintenance and repairs on time, and from the huge costs of repairs and It also prevented them from being disabled. In other words, timely and regular use of vibration analysis services is among the diagnostic measures of mechanical defects of industrial equipment before these defects become more acute.

If you have a vibration problem or frequent failure of parts in your equipment, contact our experts to get a solution