Bearings

Bearings

The wheel of industry moves with bearings, today bearings are inseparable parts of factories and industries such as agriculture, automotive, steel, petrochemical and other industrial sectors. The literal meaning of the word bearing is a part of a machine or equipment that allows other components of that device to rotate or move in contact with another part with the least possible friction.

Bearings are used in devices and equipment that have rotating components to stabilize the position, control and maintain moving parts, and depending on the applications, there are different types of them.bearings are component of agriculture, automotive, factories and other industrial sectors.

Bearings are mechanical parts that reduce the friction of parts and actually enable specific relative movement between two parts, which is typically in the form of rotation or linear movement.

Types of bearings

Bearings are made in different shapes according to the type of application, each of which has its own characteristics. According to the rotation speed, the applied force, off-axis and the desired space, the type of bearing used can have many differences. According to the type of movement, bearings are divided into two types.

Sliding bearings

Rolling bearings

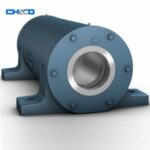

Sliding bearing

In sliding bearings, the axis is inside the bearing hole. (such as bushy bearings) Of course, by placing a layer of lubricant between the surfaces, the amount of friction can be significantly reduced. The material of these bearings can be different materials such as babbitt, bronze, copper-lead, cast iron, carbon and Teflon.

Rolling bearing

The main task of roller bearings is to reduce friction. To better explain the function of this issue, it can be explained in this way that when the components of ball bearings or rollers are spherical, cylindrical or conical, the friction changes from sliding to rolling friction, and because of this that the rolling parts roll by point or linear contact surface can reduce the friction coefficient to a great extent.

The friction of rolling bearings at the beginning of their rotation and movement is doubled when these parts are moving, but despite this, their friction is very low compared to sliding bearings.